Zone weighting is pretty simple, but it has a big impact on zoning system design with multi-stage equipment. It increases energy efficiency and allows you to design smaller zones. It also just makes sense. Here’s how zone weighting works, and why it matters.

When you design a zoning system, you have to consider the size of the equipment and the size of each zone. You might have the full CFM of the equipment directed toward your smallest zone. So the smallest zone has to be able to handle the tonnage of your equipment.

If the smallest zone can’t handle the full tonnage of your equipment, you may have to add a bypass to relieve excess static pressure. Or you might have to redesign the system.

The only problem is that redesigning the system might compromise your clients’ comfort. Adding bypass can be fine, but it does make the system less efficient, especially if it’s a large bypass.

Arzel has a better solution for multi-stage applications. You can use zone weighting to get more flexibility with your design, and better operation after installation.

Arzel’s advanced zoning systems separate Y1 and Y2 condenser and air handler terminals. This separation allows us to control the staging of the outdoor unit separately from the indoor unit. The indoor unit will then stage up and down based on the zone weighting feature. Then the outdoor condenser unit will stage based on ductwork, temperature, and time.

This type of operation is available with Arzel’s HeatPumPro, GTPro, and our upcoming Pro Panel. We recommend the HeatPumPro for most residential applications, and it is especially effective for multi-stage equipment and dual fuel. And it’s not just for heat pumps! HeatPumPro is compatible with conventional equipment as well as heat pumps.

When you’re using the HeatPumPro or GTPro with single-stage equipment, you can ignore the settings for zone weight and air handler stage threshold. These settings won’t have any impact on the system unless you’re using it with multi-stage equipment. See our static pressure guide for other ways to handle static pressure in single-stage applications.

Zone weighting is a feature that allows you to set a weight for each zone. This weight will be the percentage of total ductwork that the zone contains. You don’t need to calculate an exact percentage; an estimate is great. The percentages don’t even need to add up to 100%.

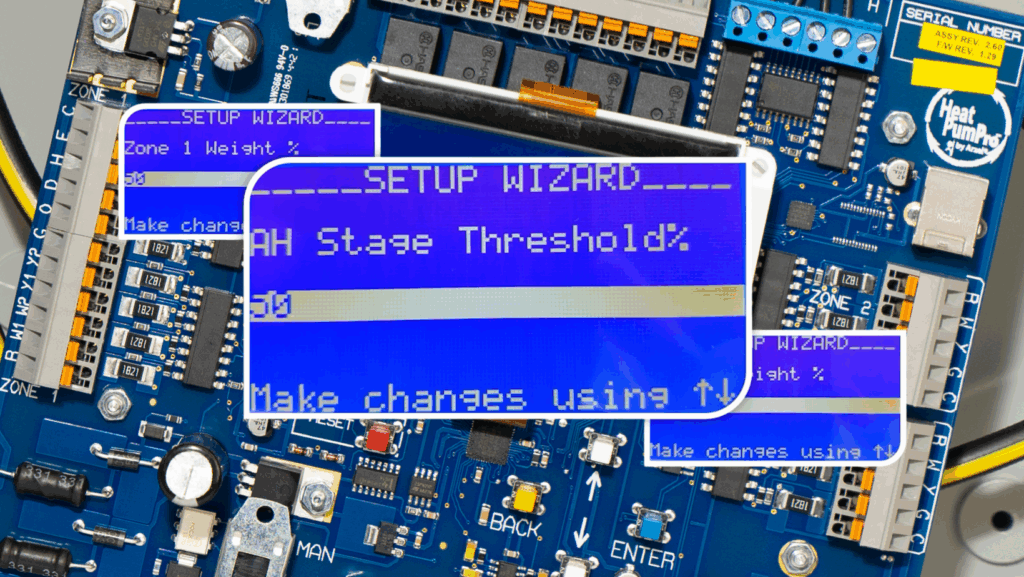

Then you’ll set the air handler stage threshold. This is the percentage of ductwork that needs to be open for the blower in the furnace or air handler to stage up.

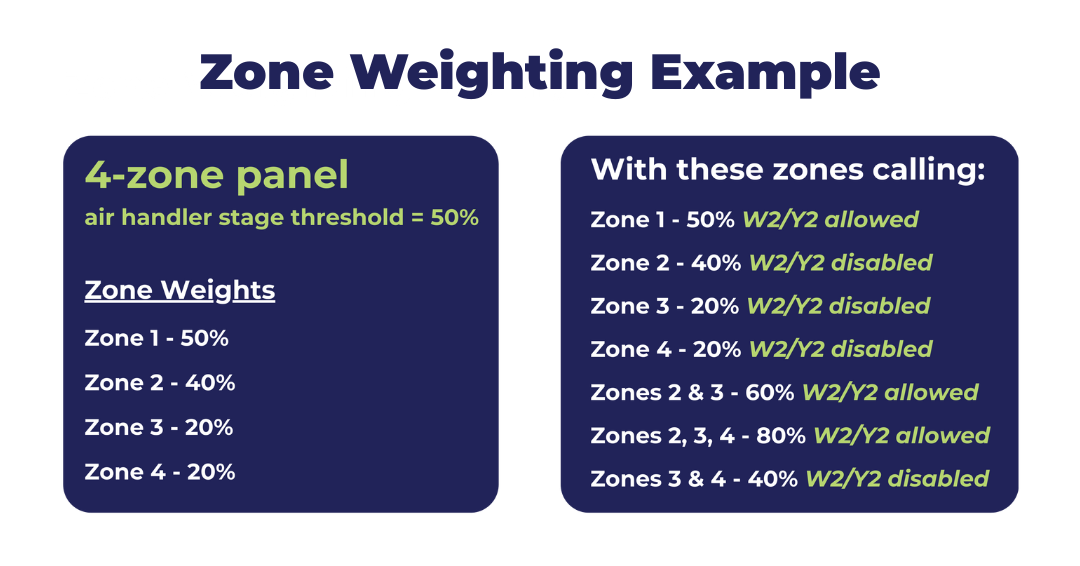

Here’s an example of how you might set up a zoning system:

In this example, you’re locking out second-stage blower operation until three zones call together. If one or two zones call, they will stay in first-stage air handler.

You could set the air handler stage threshold higher or lower depending on the equipment size and how it compares to the size of each zone. For example, 55% would allow some combinations of 2 zones to engage second-stage, but not the smaller ones like zones 1 and 4. If you set the air handler stage threshold to 80%, then you’d lock out second-stage until your 3 largest zones call together.

The biggest benefit of zone weighting is the flexibility it gives you in system design. Without zone weighting, we recommend making your smallest zone at least 33% of the ductwork. When you use zone weighting, the smallest zone can be as small as 25% of the ductwork. When you stick to these recommendations you usually don’t need a bypass, and if you do, it’s small. Being able to create smaller zones without the drawbacks of a large bypass will give your clients better comfort.

Zone weighting also leads to better energy efficiency. Think about it. Zoning directs airflow more precisely to the places it’s needed. That means you’re not sending extra conditioned air to spaces when they don’t need it. That’s just how zoning works, even before you add zone weighting. When you add zone weighting, you multiply this effect. The equipment can stay in first-stage blower operation for more runtime, leading to less energy usage overall. This case study on multi-stage equipment showed these effects.

Finally, since the panel controls staging, you can use regular heat/cool thermostats instead of multi-stage thermostats. This will save your customer some money, and it also gives them the flexibility to use any thermostat they want. They’re still getting the staging benefits of high-end equipment.

Zone weighting controls staging for the air handler, but not for heating and cooling. Condenser staging and heat staging are controlled by the temperature in the ductwork. You’ll set a heat stage threshold and a cool stage threshold, and the Arzel panel will tell the equipment to stage up if the air in the ductwork can’t reach that temperature. This temperature is monitored by the leaving air temperature (LAT) sensor.

Let’s look at some zoning applications and consider how to use zone weighting with them.

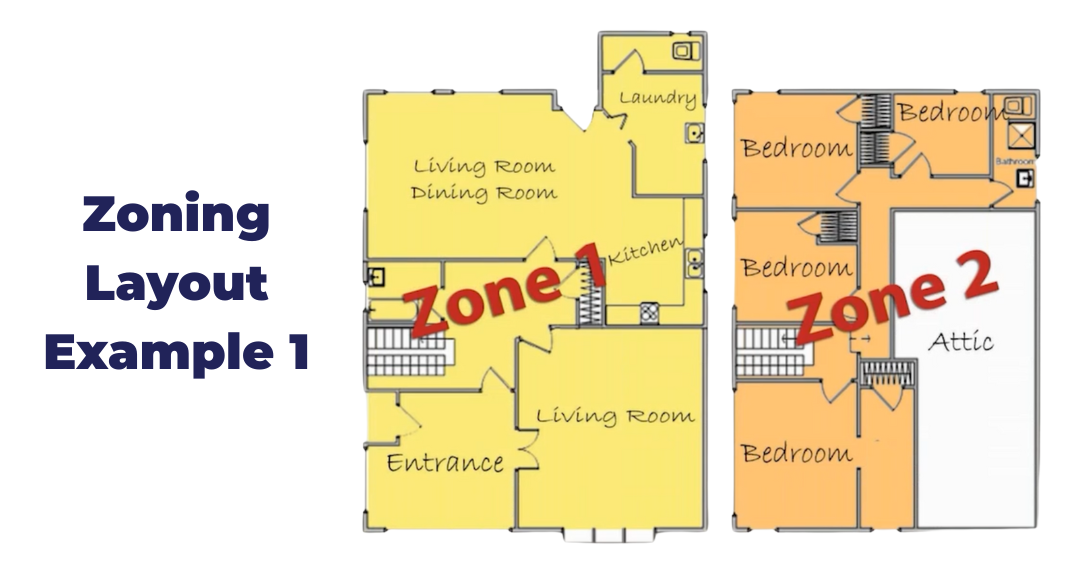

Example 1 is a typical two-story house. It probably needs to have two zones: upstairs and downstairs. When you’re splitting it into zones, you’ll want to think about whether it’s a 50/50 split. Load calculations can help you figure this out. Look at the outputs in each zone as well, and see if they are about the same CFM. If your zones are unequal, you may need a bypass. But you can use the zone weighting feature to try to minimize the size of the bypass, or eliminate the need for bypass completely.

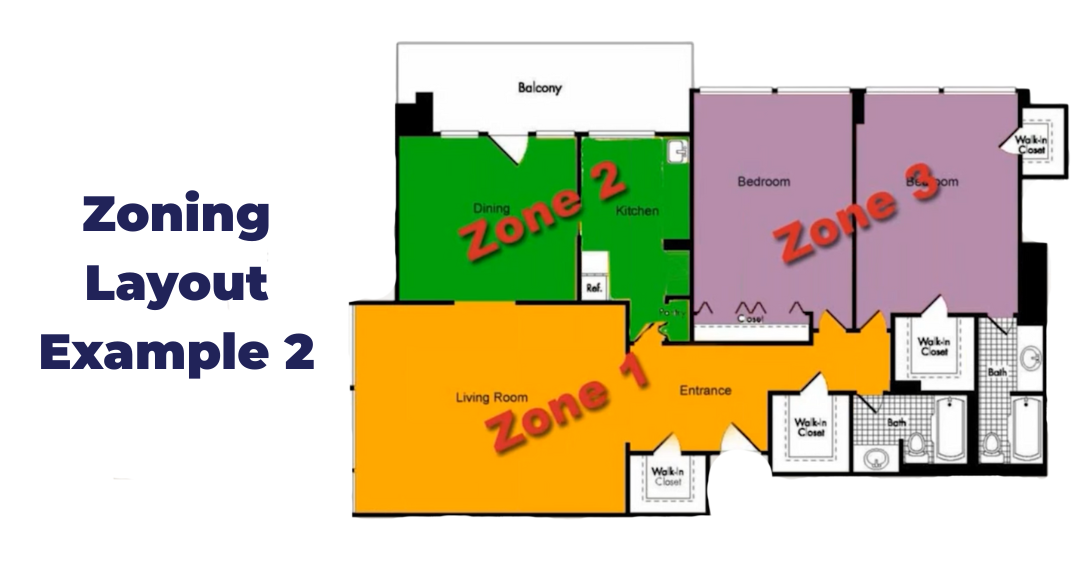

Example 2 is a three-zone ranch. The zones all look somewhat even. But do you think that zone 3 might have any complaints? Maybe you want to split the bedrooms into separate zones. But those zones will be really unequal. When one of them calls by itself, it will likely have too much CFM going into ductwork that can’t handle it. If you wanted to split those 2 bedrooms into separate zones, we might recommend using a Smart Zone (sometimes called a slave zone). A Smart Zone operates dampers but does not control the equipment. A Smart Zone will only operate when another zone is already calling for conditioning, so you won’t have to worry about overloading a small zone with the full CFM of the equipment.

You might be able to use zone weighting instead, to give your clients even more control here. You can lock out second-stage operation on smaller zones, like zone 2, or if you decide to split zone 3 into two smaller zones. Zone weighting might reduce the size of the bypass required here, or eliminate the need for bypass completely.

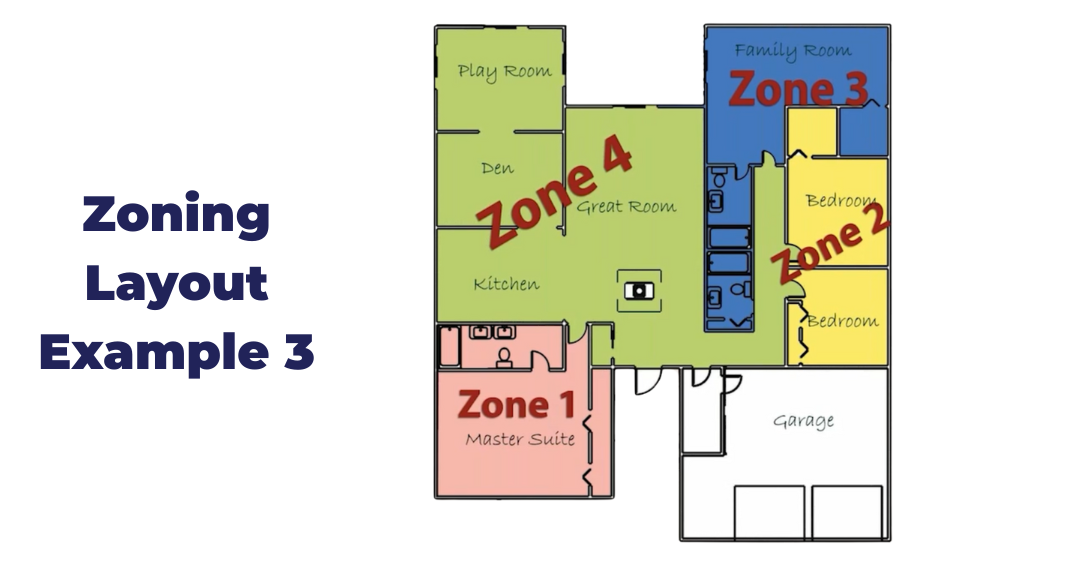

Four zones is the maximum we recommend for most houses. Example 3 has four zones, but you’ll notice they aren’t very equal. The smaller zones here could present a problem if they call by themselves and have the full CFM of the equipment. This is a great use case for zone weighting. If you lock out second-stage operation when the smaller zones are calling by themselves, then your smaller zones will only need to handle the CFM of first-stage operation.

Here’s one more example to show how to set up zone weighting with the HeatPumPro. First, you’ll assign a zone weight to each zone. Then, you’ll set the air handler stage threshold. These settings work together to lock out second-stage operation when there isn’t enough ductwork open.

If the total zone weight is equal to or greater than the air handler stage threshold, the system allows for second-stage operation.

In this example, the air handler stage threshold is 50%. When you look at zone 1, the zone weight is also 50%. So when zone one calls by itself, second-stage operation is allowed.

Zone 2 has a zone weight of 40%. If zone 2 is calling by itself, it will not be able to go into second-stage operation. Second-stage operation is locked out until another zone calls and makes the total zone weight reach the 50% air handler stage threshold.

For zones 3 and 4, you’ll see they both have a zone weight of 20%. Neither one of these zones meets the air handler stage threshold by itself, so they are locked out of second-stage operation if they are calling alone. They also cannot go into second stage if they call together, because they will still not meet the air handler stage threshold. But if one more zone calls, they will meet the threshold and second-stage operation will be allowed.

The zone weight percentages don’t have to be any kind of exact calculation. They also don’t need to add up to 100%. The important thing to think about is whether the zone weight equals the air handler stage threshold. That will determine which zones are allowed to have second-stage operation, and which ones are locked out.

Our new Pro Panel control can zone up to 16 zones. That’s twice as many as our biggest AirBoss, and four times what our HeatPumPro can do. With 16 zones possible, the Pro Panel can be a zoning solution for more light commercial buildings and large houses. On top of the additional zones that are […]

The Arzel Pro Panel app gives contractors more control, easier setup, and better troubleshooting capabilities. All of that comes in a no-nonsense package. The app is simple to connect and doesn’t require Wi-Fi or cell service. We’re proud that the Arzel Pro app makes the Pro Panel our most customizable panel. And it’s still easy […]

App-controlled HVAC zoning panel is feature-rich and highly customizable; pairs with trusted Arzel dampers Cleveland, OH (Feb. 10, 2026) – Arzel Zoning Technology, a trusted name in HVAC since 1983, is proud to announce a new zoning control: The Pro Panel™. This universal zoning control offers advanced control and a feature rich system, all with […]

An Arzel zone system can solve several comfort issues for your customers. How do you know when to recommend Arzel, and when you need to look for another solution? Here’s what an Arzel Zoning system can do, and what it can’t. Find the best solution for your customer’s needs with this guide. It’s Too Hot […]