Low-Voltage Troubleshooting: How to Beat the Heat and Find the Problem

Nothing is more frustrating than low-voltage troubleshooting when it’s hot, the calls are piling up, and you’re getting home just in time for bed. Or choosing to sleep in the truck as the on-call technician. I remember those days, and while I might not have that anymore, providing tech support at Arzel reminds me that low voltage is still one of the most problematic areas for technicians.

Being more effective in troubleshooting low-voltage circuits helps everyone, from the homeowner to the factory tech support. Mainly it helps you to do your job better, with happier customers. With that in mind, here are some tips to help you or someone you know.

For Low-Voltage Troubleshooting, Test Resistance

Resistance tests quality; continuity doesn’t. One of the most valuable lessons I’ve learned is to check resistance, or ohms (Ω). As HVAC technicians, we work mostly with switches that are automated by different parameters. This circuit engages that circuit, this circuit is temperature controlled, this one is draft controlled, this one is pressure controlled. Every low voltage circuit has a hot and a common or neutral. Power flows from hot to ground, powering the circuits it passes through. Testing the resistance in these circuits should be the first step in low-voltage troubleshooting.

How Low Voltage Circuits Work

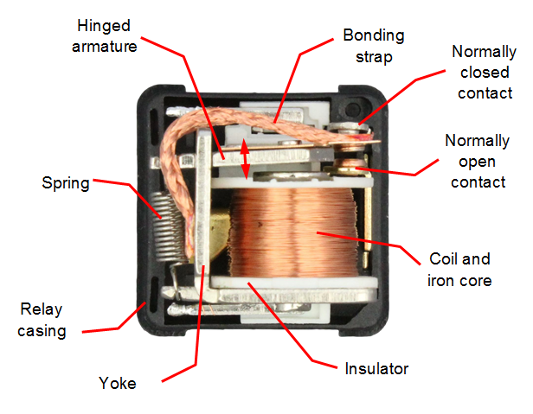

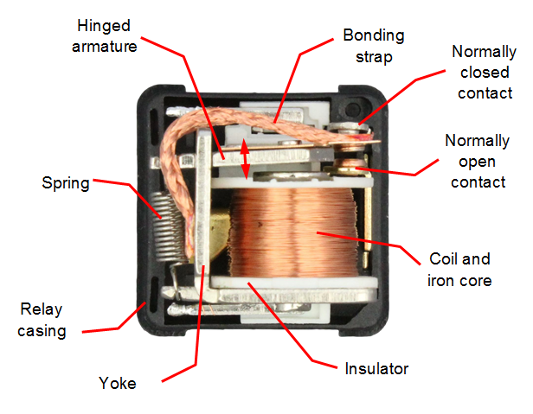

Before you begin low-voltage troubleshooting, make sure you know how the circuits work. See the diagram for a visual example. When the coil is energized, the normally open contact is pulled closed, and the normally closed contact opens. The circuit can be tested for resistance by checking between the contacts “Common” and the NC or NO terminals. If the contact is open, you should read OL or ∞. If the contact is closed, you should see less than 1Ω of resistance.

Most everything in the low voltage circuit of the HVAC system is controlled by a series of these contact points. The thermostat has a bank of relays, zoning panels have a bank of relays, and the furnace circuit board has many relays. The outdoor unit has contactors which are functionally the same as relays but are typically rated for a higher current. Even safety switches, like the high and low pressure switches in the outdoor unit are simply a closed contact point. Draft switches on an inducer motor are normally open, and then close when sufficient draft is proven. It is important to know how these components work because then we can be certain whether they are good or bad. And it is always better to know than to make assumptions.

We’re going to focus on a thermostat for this blog, but testing a contact is functionally the same, no matter the device.

Low-Voltage Troubleshooting: Thermostat

There are pins on the back of a thermostat, and the relays make a connection between R and the heating or cooling operation (W1, W2, Y1, Y2, G, O). Calls for operation depend on whether we have a heat pump or an air conditioner, and also whether the HVAC equipment is single stage or two stage.

Test the Resistance

Let’s look at the most basic operation. A call for heating makes a connection between R and W. A call for cooling connects R, Y, and G. If the thermostat has batteries, locate the pin for R and the pin for W, Y, or G. Those contacts can be tested to verify that the thermostat is outputting heating or cooling. If R-W is greater than 1Ω and the thermostat is calling for heating, then the thermostat is bad. The same is true for R-YG. If you measure greater than 1Ω of resistance in that connection, and the thermostat is calling for cooling, then you know that the thermostat is bad.

Never assume a new thermostat is good if the system isn’t working. In tech support here at Arzel Zoning, we’ve been on the phone with technicians who assumed the thermostat they just installed was working correctly. But when they tested the resistance, they proved that the thermostat was DOA. Assumptions can waste time and make those summer days a lot longer than they need to be.

Testing resistance is the surest way to prove a circuit, but it isn’t always possible. Testing resistance requires one side of the circuit to be disconnected so we’re only testing the contact point, not the entire circuit. If testing resistance isn’t feasible, the next best way is to test the voltage.

Test the Voltage

When testing voltage you need to check in a few places. (Make sure you do this! Neglecting it could send you on a wild goose chase.)

- R-C should read 24vac. If this reads 0 then you need to check the transformer. Then look for faulty fuses and safety switches. Condensate safety switches are a common cause of equipment not operating during the cooling season. If the R-C reading is correct, move on to step 2.

- Test R-W or R-YG as well as C-W or C-YG. If the contact is open R-W or R-YG will read 24vac. If the contact is closed, it will read 0vac. In this case, you will still need to test to C.

- The reading for C-W or C-YG should read 24vac if the contact is closed and 0vac if the contact is open. Any other reading means there’s a problem. If there’s a split voltage R-function 6vac and C-function 18vac, then it’s a bad contact point. The contacts are burned or pitted.

This testing sequence works for high-voltage circuits as well. And here’s a pro-tip for the contactor in the outdoor unit: if you have greater than a 1vac difference between the incoming and outgoing side of the contactor it’s time to recommend replacement. The contacts are burned or pitted. For example, you might read 238.6vac in and 237.6vac out.

By testing both directions you can move past assumptions and know for certain if something is contributing to the problem you’re there to diagnose.

The Last Step of Low Voltage Troubleshooting

In addition to testing relays, you’ll need to know the sequence of operation. Test the system from point A to point Z, ruling out components one at a time until you arrive at the cause of failure. This approach will save you a lot of frustration. And when the schedule is slammed, it will also optimize your time by saving you callbacks.

Use a True RMS Meter

As a last note, get a decent meter! There’s nothing more frustrating than using a meter that has more functions than necessary. Or one that’s not made for the application. True RMS meters are necessary.

This isn’t a paid promotion but my current meter is the Fieldpiece SC440. I’ve used Fieldpiece for nearly 20 years. They are simple, reliable, and have all the functions necessary for the HVAC tech. Today as a factory technician I rarely need to guess if the Fieldpiece guys have their meter set to the correct function.

Written by JR, Arzel Tech Support